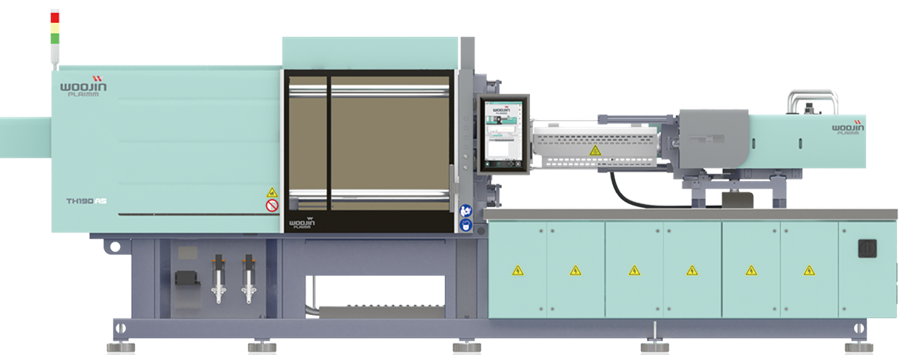

TH-A5 series

Energy saving hydraulic toggle injection molding machine

- Fully hydraulic toggle machine (1300 bis 4800 kN Clamping force)

- Injection unit IH170 up to IH2900

- Compact Design and highly energy efficient

- Control Unit IMC 500

- Energy Saving Hydraulic Servodrive System

- High efficient toggle system

- FEA optimized moving platen

- Precise injection unit

TH-A5

TH-A5

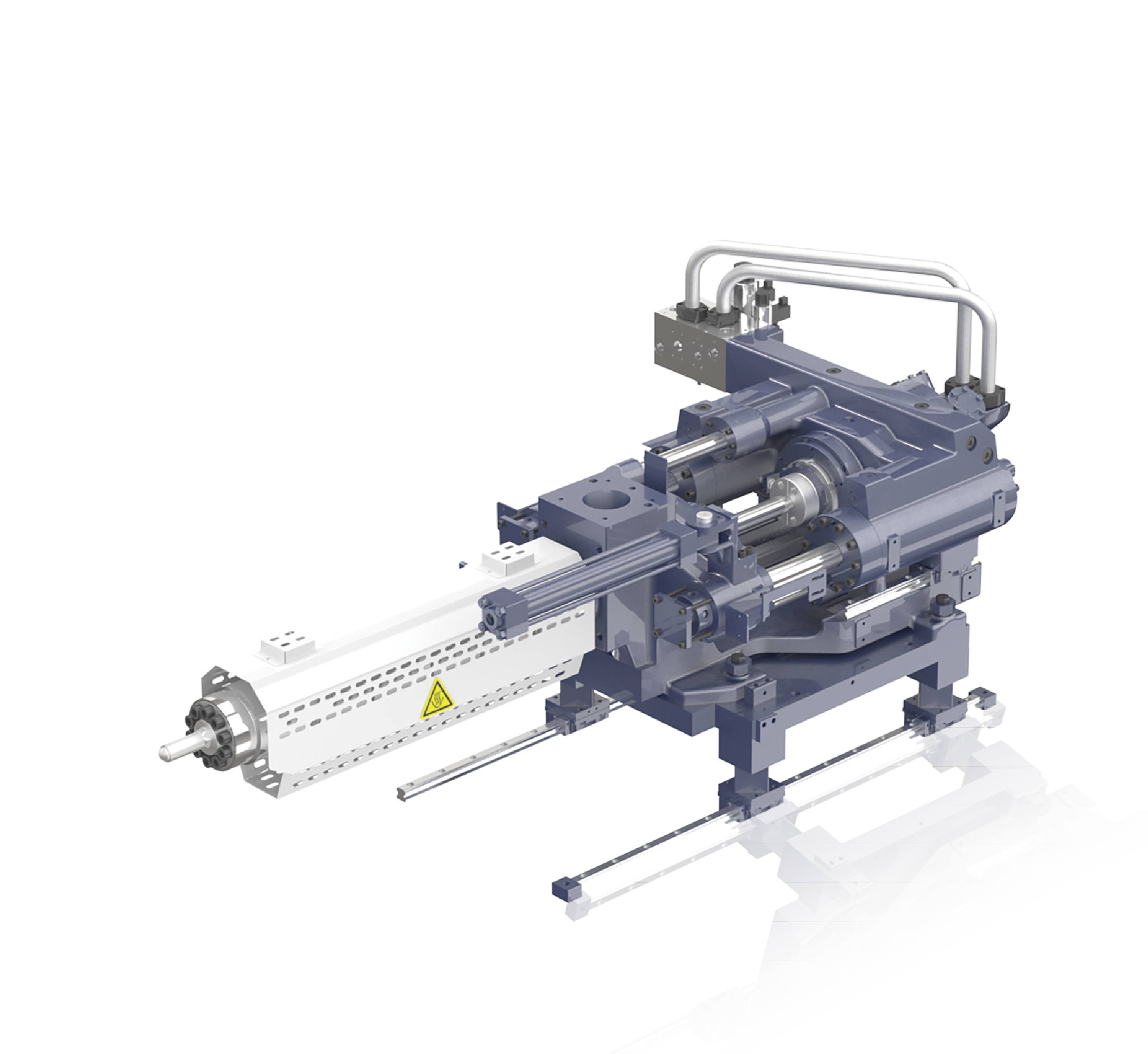

Injection unit

- Fast and rigid bi-axial injection cylinder:

Faster speed and improved responsiveness. - High performance plastication unit:

Prepared for the production of advanced technical parts. - Precise and powerful screw drive:

Ensures the processing of a large variety of raw material. - Diagonal pull nozzle touch cylinder:

Ergonomic design for user-friendly accessibility. - Low friction LM guide:

Accurate and energy efficient movement. - Closed-loop proportional back pressure control:

Guaranties a precise and stable injection.

TH-A5-Injection

TH-A5-Injection

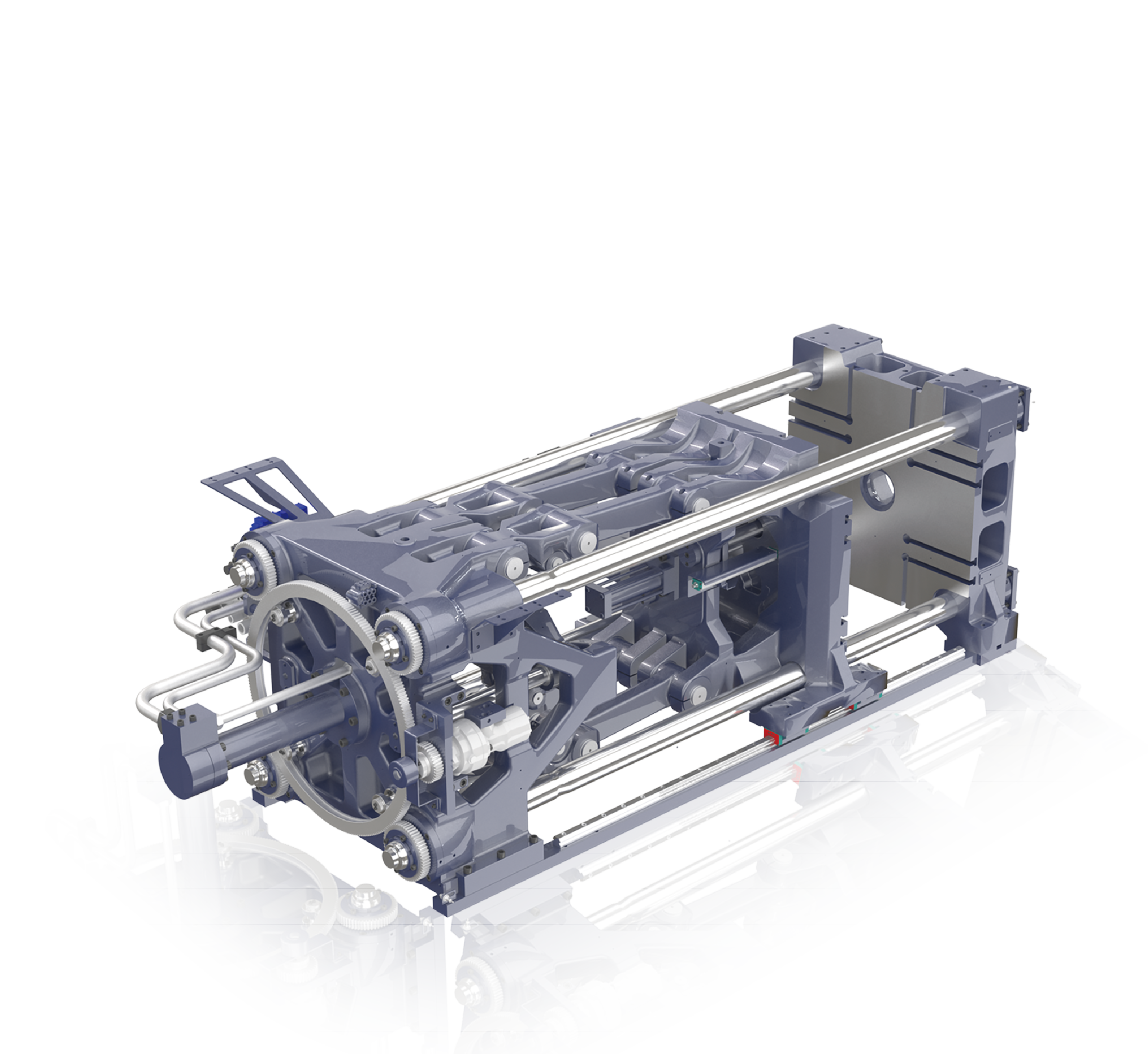

Clamping unit

- Energy efficient toggle system:

Fast opening and closing stroke and clamped-type toggle pin fixation to increase durability. - Linear guided moving platen:

Accurate and energy efficient movement. - Modular hydraulic core system:

Ease scalability with modular hydraulic core applications. - Wide tie-bar distance and long stroke:

Prepared for large mold. - Mold height adjustment:

Precise adjustment of stroke by encoder control. - FEA optimized moving platen:

Rigid platen ensures homogenous applications of force.

TH-A5-Clamping

TH-A5-Clamping

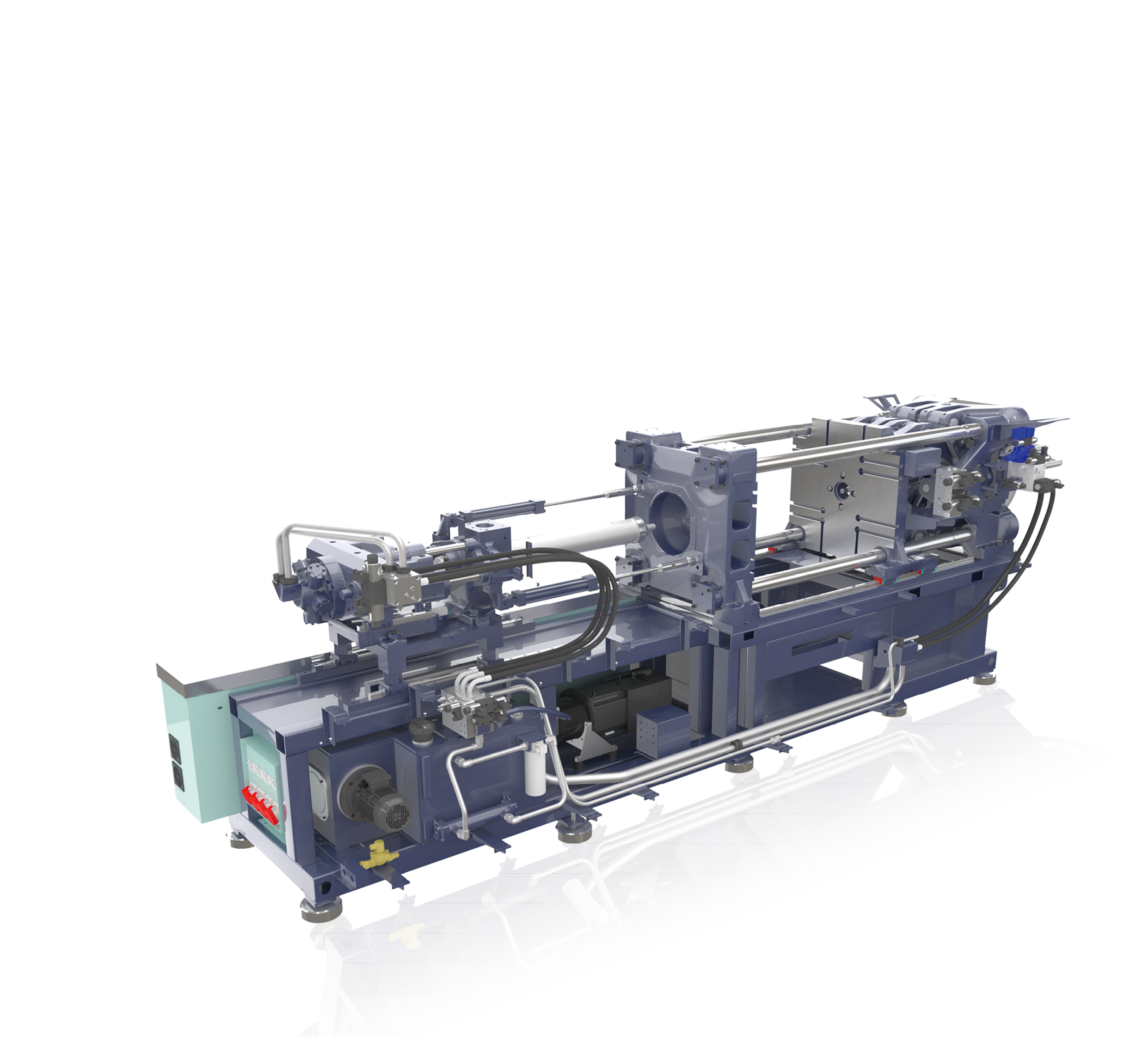

Hydraulic unit

- High efficiency servo pump system:

Is included in standard configuration saves energy and reduces costs. - Seamless pipe system:

Saves energy compared to hoses. - Hydraulic block with special coating:

Anti-corrosion and cleanliness with nickel coating inside and outside the block. - Independent pump for filtering and cooling:

Increase lifespan of hydraulic oil and saving of maintenance costs. - Optional second servo pump:

Enable parallel movements of ejector and cores.

TH-A5-Hydraulic

TH-A5-Hydraulic

* The images and specifications might be changed without any prior notice for optional purpose and / or quality improvement.